MIT researchers have developed a reconfigurable antenna that dynamically adjusts its frequency range by changing its physical shape, making it more versatile for communications and sensing than static antennas.

A user can stretch, bend, or compress the antenna to make reversible changes to its radiation properties, enabling a device to operate in a wider frequency range without the need for complex, moving parts. With an adjustable frequency range, a reconfigurable antenna could adapt to changing environmental conditions and reduce the need for multiple antennas.

The word “antenna” may draw to mind metal rods like the “bunny ears” on top of old television sets, but the MIT team instead worked with metamaterials — engineered materials whose mechanical properties, such as stiffness and strength, depend on the geometric arrangement of the material’s components.

The result is a simplified design for a reconfigurable antenna that could be used for applications like energy transfer in wearable devices, motion tracking and sensing for augmented reality, or wireless communication across a wide range of network protocols.

In addition, the researchers developed an editing tool so users can generate customized metamaterial antennas, which can be fabricated using a laser cutter.

“Usually, when we think of antennas, we think of static antennas — they are fabricated to have specific properties and that is it. However, by using auxetic metamaterials, which can deform into three different geometric states, we can seamlessly change the properties of the antenna by changing its geometry, without fabricating a new structure. In addition, we can use changes in the antenna’s radio frequency properties, due to changes in the metamaterial geometry, as a new method of sensing for interaction design,” says lead author Marwa AlAlawi, a mechanical engineering graduate student at MIT.

Her co-authors include Regina Zheng and Katherine Yan, both MIT undergraduate students; Ticha Sethapakdi, an MIT graduate student in electrical engineering and computer science; Soo Yeon Ahn of the Gwangju Institute of Science and Technology in Korea; and co-senior authors Junyi Zhu, assistant professor at the University of Michigan; and Stefanie Mueller, the TIBCO Career Development Associate Professor in MIT’s departments of Electrical Engineering and Computer Science and Mechanical Engineering and leader of the Human-Computer Interaction Group at the Computer Science and Artificial Intelligence Lab. The research will be presented at the ACM Symposium on User Interface Software and Technology.

Making sense of antennas

While traditional antennas radiate and receive radio signals, in this work, the researchers looked at how the devices can act as sensors. The team’s goal was to develop a mechanical element that can also be used as an antenna for sensing.

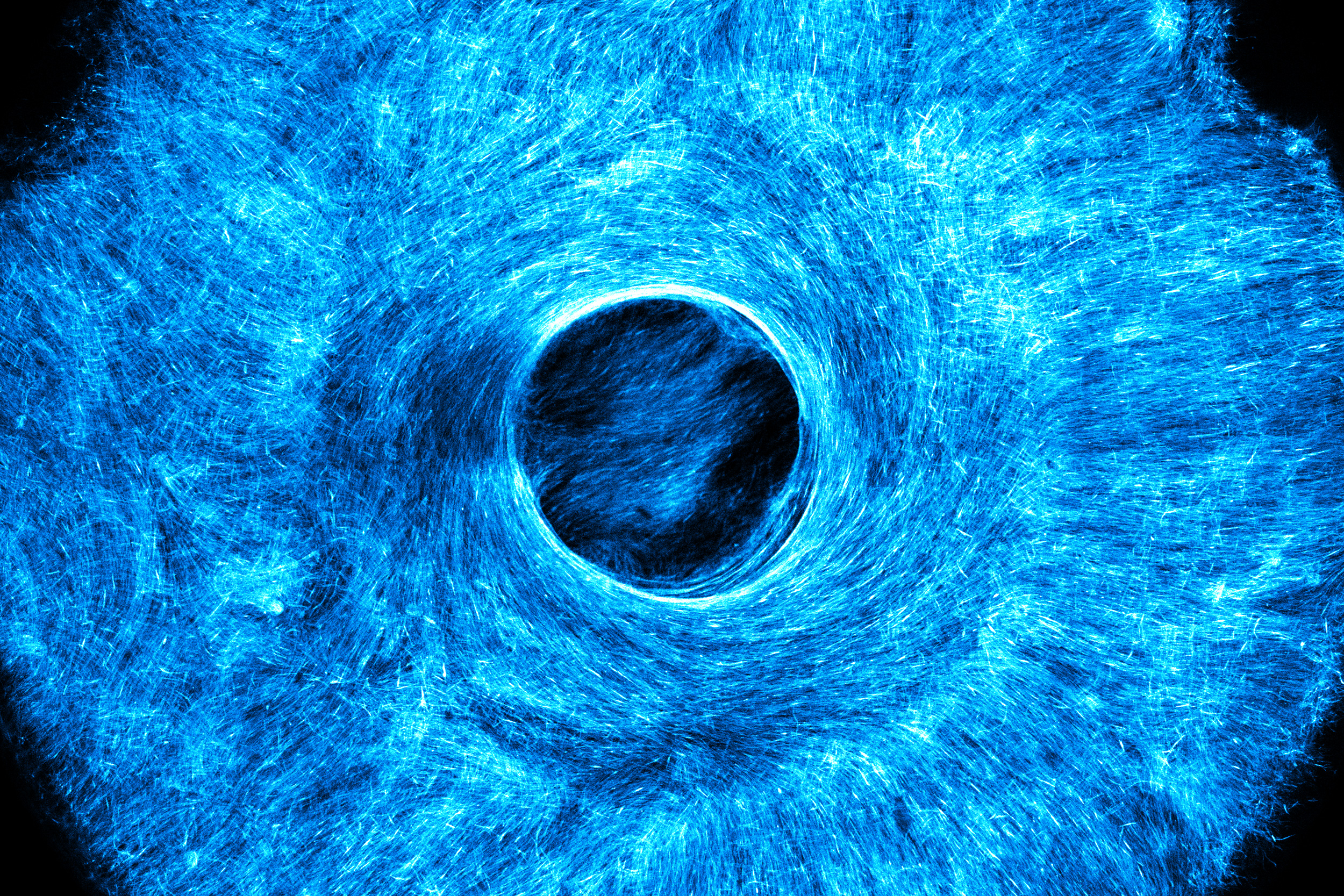

To do this, they leveraged the antenna’s “resonance frequency,” which is the frequency at which the antenna is most efficient.

An antenna’s resonance frequency will shift due to changes in its shape. (Think about extending the left “bunny ear” to reduce TV static.) Researchers can capture these shifts for sensing. For instance, a reconfigurable antenna could be used in this way to detect the expansion of a person’s chest, to monitor their respiration.

To design a versatile reconfigurable antenna, the researchers used metamaterials. These engineered materials, which can be programmed to adopt different shapes, are composed of a periodic arrangement of unit cells that can be rotated, compressed, stretched, or bent.

By deforming the metamaterial structure, one can shift the antenna’s resonance frequency.

“In order to trigger changes in resonance frequency, we either need to change the antenna’s effective length or introduce slits and holes into it. Metamaterials allow us to get those different states from only one structure,” AlAlawi says.

The device, dubbed the meta-antenna, is composed of a dielectric layer of material sandwiched between two conductive layers.

To fabricate a meta-antenna, the researchers cut the dielectric laser out of a rubber sheet with a laser cutter. Then they added a patch on top of the dielectric layer using conductive spray paint, creating a resonating “patch antenna.”

But they found that even the most flexible conductive material couldn’t withstand the amount of deformation the antenna would experience.

“We did a lot of trial and error to determine that, if we coat the structure with flexible acrylic paint, it protects the hinges so they don’t break prematurely,” AlAlawi explains.

A means for makers

With the fabrication problem solved, the researchers built a tool that enables users to design and produce metamaterial antennas for specific applications.

The user can define the size of the antenna patch, choose a thickness for the dielectric layer, and set the length to width ratio of the metamaterial unit cells. Then the system automatically simulates the antenna’s resonance frequency range.

“The beauty of metamaterials is that, because it is an interconnected system of linkages, the geometric structure allows us to reduce the complexity of a mechanical system,” AlAlawi says.

Using the design tool, the researchers incorporated meta-antennas into several smart devices, including a curtain that dynamically adjusts household lighting and headphones that seamlessly transition between noise-cancelling and transparent modes.

For the smart headphone, for instance, when the meta-antenna expands and bends, it shifts the resonance frequency by 2.6 percent, which switches the headphone mode. The team’s experiments also showed that meta-antenna structures are durable enough to withstand more than 10,000 compressions.

Because the antenna patch can be patterned onto any surface, it could be used with more complex structures. For instance, the antenna could be incorporated into smart textiles that perform noninvasive biomedical sensing or temperature monitoring.

In the future, the researchers want to design three-dimensional meta-antennas for a wider range of applications. They also want to add more functions to the design tool, improve the durability and flexibility of the metamaterial structure, experiment with different symmetric metamaterial patterns, and streamline some manual fabrication steps.